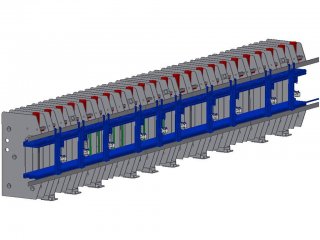

The HSDP hydraulic clamp is designed for gluing boards - mainly floorboards, square-sawn timber and various wooden shapes by thickness. Gluing is done under high pressure from the hydraulic actuators. The pile of glued elements is formed by the hydraulic pressing between the actuator beams and the stopping beams. Gluing by thickness allows the shaping of any profile, lowers the cost of working, and decreases the amount of scrap material. The operation of the press as an appliance serving to glue wooden elements under pressure does not require the operator to have any special qualifications. The machine is simple in its functioning, and when the proper care is taken, safe. The HSDP machine has the capability of individual control of every loading field by means of the divider of the appropriate field. The control capabilities should be defined according to the attached hydraulic scheme. Selection of the appropriate work variant consists of cutting off power to unused actuators by means of cut-off valves. The valves are located on the power thread before certain actuators.

| TECHNICAL AND OPERATIONAL DATA: | ||

| Amount of loading fields | qt. | 6(3x2500,2000,2x1000) (*) |

| Maximum strip width | mm | 400 (*) |

| Loading field dimensions: - loading height - board length in one field |

mm mm |

max 600 max 2500 (*) |

| Amount of actuators per field: | mm | φ 140x300 – 4 szt. + 2x2 szt. |

| Installed power | kW | 7,5 |

| Working voltage | V AC | 3/N/PE, 400V 50Hz |

| Control voltage | V DC | 24 |

| External dimensions: - Length - Width - maximum height |

mm mm mm |

12500 1430 2200 |

| Range of attained pressing force (per one actuator): | kN | pionowy 200 (przy ciśnieniu 14 MPa) |

| Total machine mass | kg | 17000 |

(*) – the amount of loading fields, their length, and board width can be adjusted according to negotiation with the client.